YouTube / RAAF Documentaries

In July 1968, the first test flight of the F-111C in Fort Worth, Texas, highlighted a major flaw regarding the integrity of the Aardvark’s wing box. Other issues were noted in a fatigue test a month later when the aircraft developed several issues that were traced to its poor manufacturing.

Then, on December 22, 1969, during a pull-up from a simulated rocket attack at Nellis AFB, an F-111A suffered a catastrophic failure. The inexperienced crew failed to eject due to how quickly the F-111 started rolling. Once again, the issue was traced to the wing pivot, where a crack formed due to a sharp-edged forging defect.

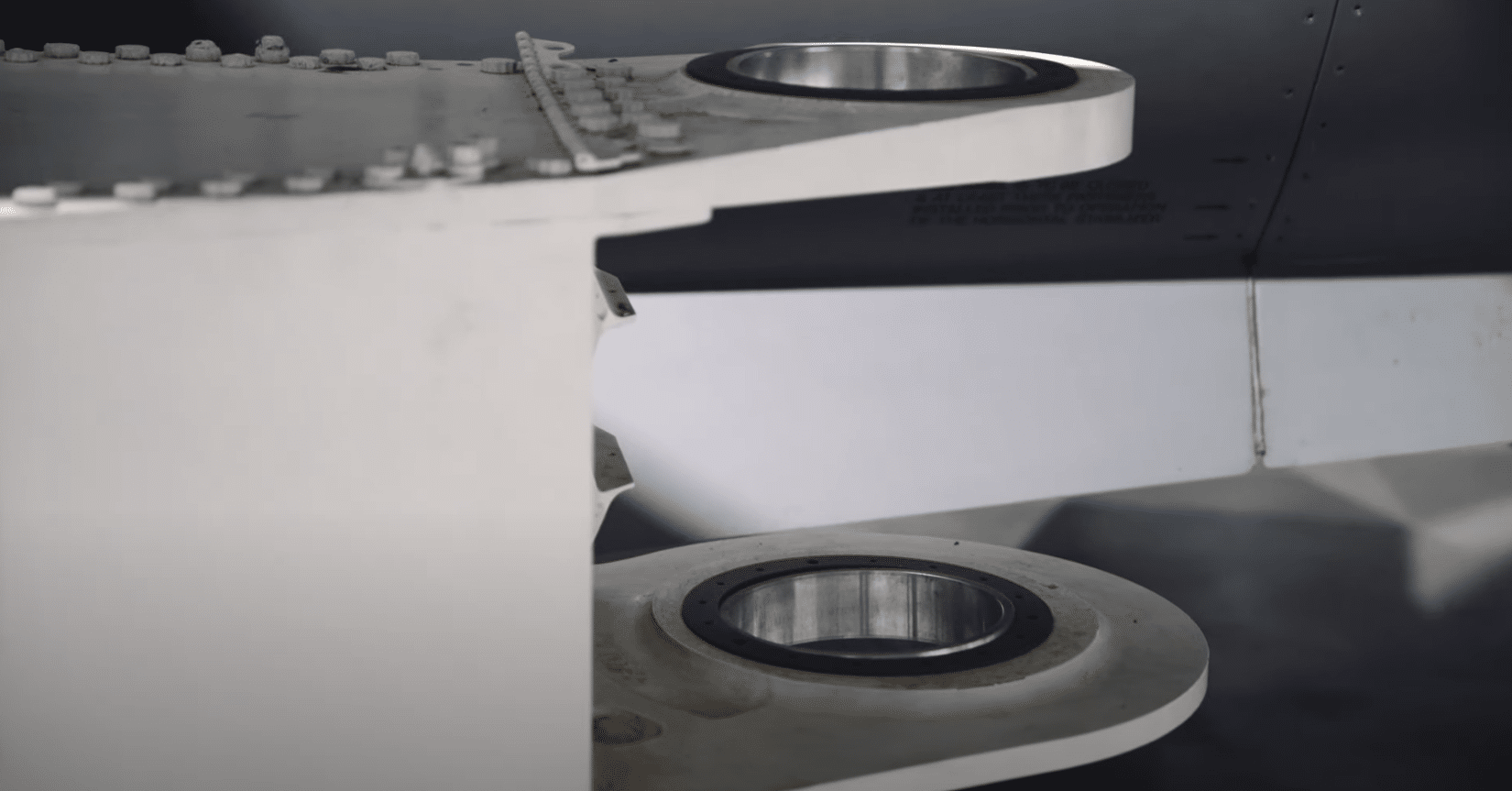

The incident occurred in the 7.62 mm lower plate of the wing pivot fitting. It was observed that a manufacturing flaw at 5.72mm deep in the plate began to grow during the flight. A crack grew to 23.6mm across the plate and 6.16mm deep – enough to become a critical failure.

The wing pivot fitting would eventually break, which led to the entire left wing flying off of the F-111.

Fortunately, the manufacturing process was slowly improved until all the fatal problems were resolved in 1973.